Ambitious targets require solutions that are not only powerful and advanced, but also smart and targeted. Container terminals face major challenges: growing volumes, increasing complexity, and the need to operate safely, swiftly, and sustainably — all at once.

At Camco Technologies, we understand that succesful automation is not just about big leaps forward, but about thoughtful, flexible innovations tailored to each terminal’s reality. Whether it’s streamlining gate operations, accurately tracking containers or preventing incidents: every improvement contributes to make terminals safer, more efficient, and future-proof.

Automatic oversize detection at the gate

Container terminals are busy hubs where gate safety is not a detail but a priority. Camco’s ARGUS system, known for automated damage inspection of incoming containers, has recently received a major upgrade: automatic oversize detection using LIDAR technology.

Where ARGUS once detected only visible damage, it now also recognizes irregular shapes or sizes in containers and trailers — such as bulging or excessive height. These anomalies often go unnoticed but pose real risks to infrastructure or cranes. Thanks to LIDAR, ARGUS now performs 3D scans and intervenes in case of oversize loads before they enter the terminal.

With this upgrade, ARGUS evolves from an inspection tool to a full-fledged safety guard. Terminals around the world using the system report fewer incidents and increased confidence in gate processes.

- Detects oversize cargo using 3D LIDAR

- Prevents damage to infrastructure and downtime

- Improves safety for staff and assets

- Enables faster, automated gate decisions

Camco’s ARGUS system, known for automated damage inspection of incoming containers, has recently received a major upgrade: automatic oversize detection using LIDAR technology.

Smart scheduling for smoother gate processes

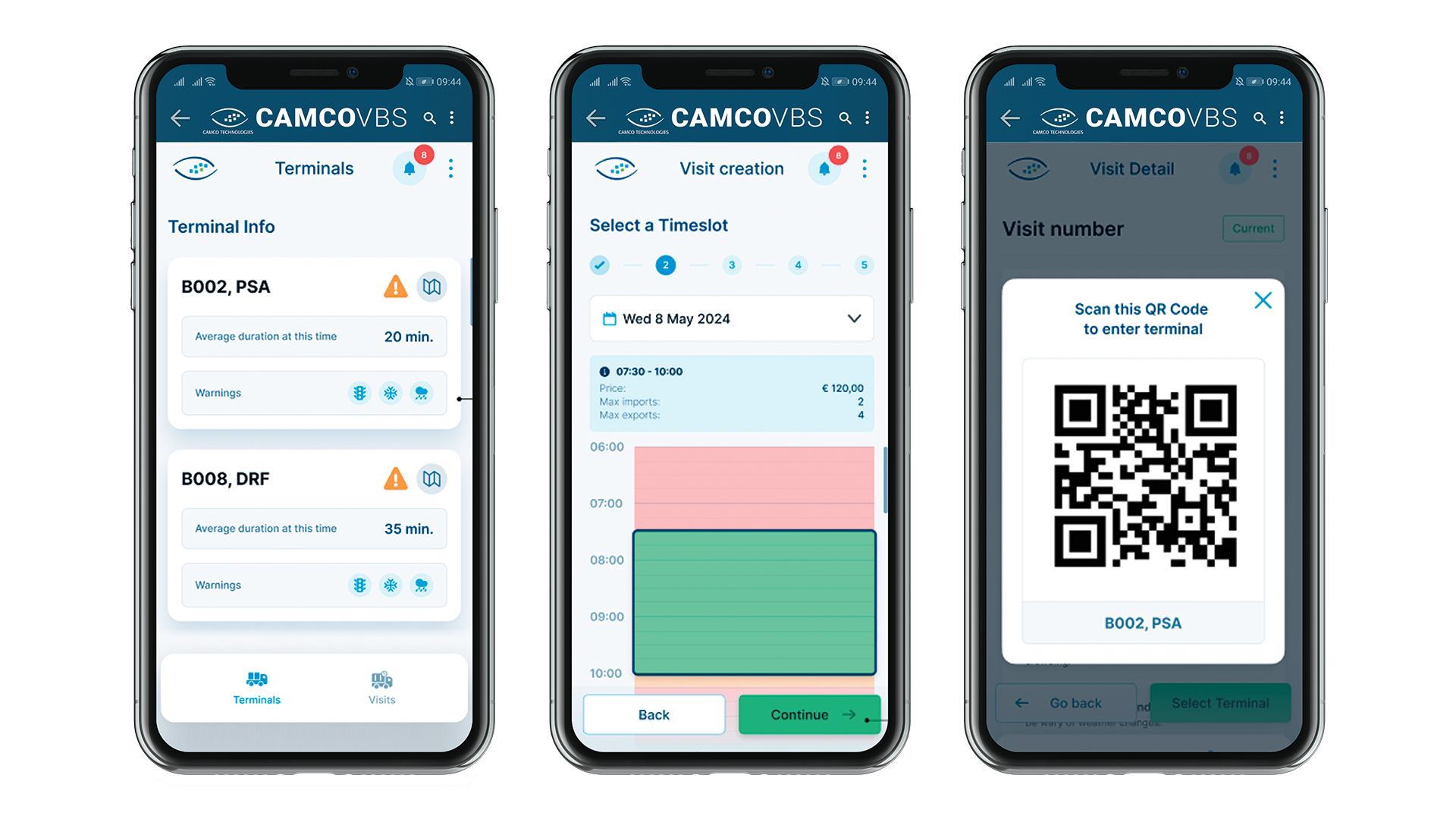

It’s increasingly common for terminal access to be managed through a Vehicle Booking System (VBS). Camco’s VBS integrated in THE BRIDGE avoids queues for trucks arriving to collect containers that are not yet available. VBS also helps flatten peak times through the use of optional timeslots.

VBS allows terminals to set quotas and time slots for container pickup and drop-off. This predictability smooths traffic flow and shortens queues. Even without strict slots, VBS functions as a robust pre-registration tool that collects visit data in advance.

Linking the booking to a truck or driver ID enables near-full gate automation via OCR cameras and kiosks. Since a strong VBS system has already handled logistics verification, the gate need only confirm the physical presence of the truck, driver, and container.

Truckers can manage appointments, complete missing info, and receive alerts via a free VBS app — all from their cab. The app boosts flexibility, improves communication, and prevents surprises at the gate.

Smarter tracking, safer movement

In a modern terminal, knowing a container’s location is just the beginning. Equally important is understanding how it moves and whether the journey is safe. Camco combines several technologies to create a complete digital shadow of every container and each vehicle transporting it.

At fixed points such as gates, AI-driven cameras ensure accurate identification through image recognition. Once inside the yard, other systems take over. Real-time location systems (RTLS) don’t track the container itself but the vehicle carrying it — like straddle carriers, terminal trucks, or reach stackers.

Camco’s RTLS – completely integrated in THE BRIDGE – relies on sensor fusion: a combination of GNSS (satellite navigation) and UWB (Ultra-Wide Band) technology. This data fusion provides location accuracy down to 5 cm — precise enough to position vehicles perfectly at STS cranes, allowing containers to be picked up without manual correction. The result: reduced waiting times, improved KPIs, and smoother vessel handling.