Pioneering innovative terminal automation solutions

Through our innovative terminal automation solutions, we empower terminal operators to increase performance and improve safety while reducing operating costs.

Pioneering innovative terminal automation solutions

Through our innovative terminal automation solutions, we empower terminal operators to increase performance and improve safety while reducing operating costs.

Discover our innovative terminal automation solutions

Regardless of the size or kind of terminal, we have the solution that suits your needs.

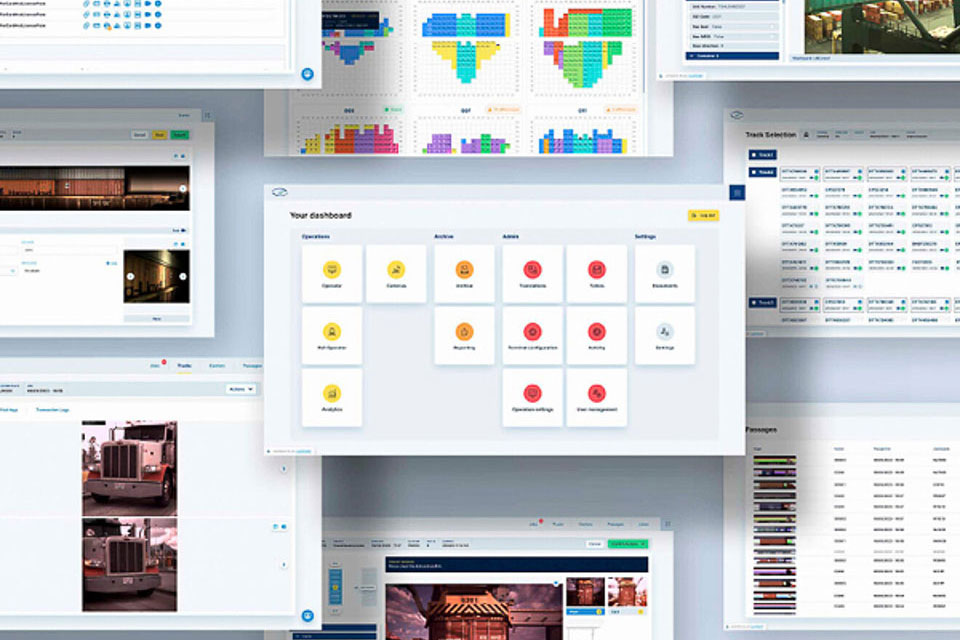

THE BRIDGE

An all-in-one interface to streamline processes with minimal operator involvement

In the past, GOS, rail OCR (ROS), RTLS, and Crane OCRs (COS) had different user interfaces. To enhance user experience and efficiency, Camco Technologies created The BRIDGE—a unified, web-based platform that connects all automation systems.

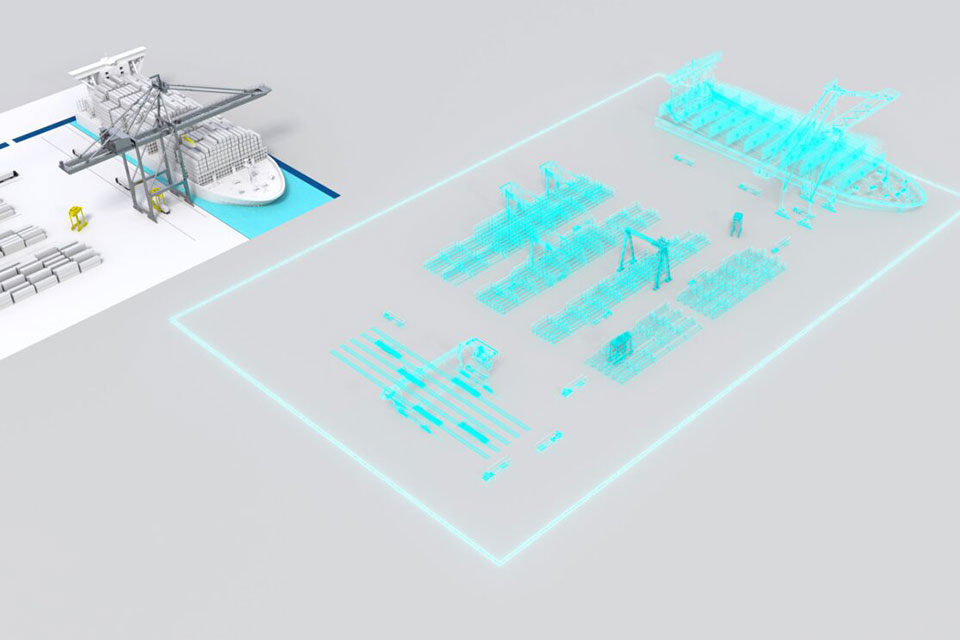

THE TWINBRIDGE

Identify weaknesses, test changes, and measure cost and performance gains

Camco Technologies leverages IoT-enabled CHE and dynamic container data to power its digital twin technology—an interactive, real-time model that optimizes terminal operations by identifying weaknesses, testing process changes, and measuring cost and performance gains.

Gate

The industry reference in vision-based gate automation solutions

Being a long-term partner for the marine and railroad industry, Camco Technologies offers a unique combination high-class products, high-end engineering and high-value expertise of terminal and gate operations. Our systems include kiosks and OCR portals, managed by our proprietary Gate Operating Systems (GOS), who in its turn seamlessly interfaces with any TOS. Finally, we lead the class in the development of next-level software solutions that integrate your complete gate automation environment into your global operations.

Quay

Improving waterside operations for a leaner, greener industry ready for increasing traffic

Camco’s groundbreaking BoxCatcher OCR effortlessly records every container movement during vessel loading and unloading. This advanced image capture and recognition system is seamlessly integrated into the crane, offering real-time exception management. But that’s not the end of our proposition: our Real Time Location System provides precise container tracking. Moreover, our proprietary software goes even further. Both our RT digital win THE TWINBRIDGE, unifying software THE BRIDGE and additional add-ons to existing hardware solutions deliver an unparalleled real-time and digital overview of your quay operations.

Yard

From a step by step integration to full integration of terminal processes

The entire logistics process of container handling relies on data. Processing this data accurately is crucial for the efficient organization of logistical operations. Camco Technologies integrates camera systems, registration kiosks, track & trace technology, as well as software applications that make the automation of container handling perfectly possible. Today, tomorrow, and beyond.

Rail

Start processing trains without delay and improve train turnaround time

Camco Technologies Rail OCR Solutions capture crucial data while trains approach the terminal, without hindering or delaying operations. Our systems preprocess, register and post-process all relevant data which optimizes planning and handling via the TOS. Our high quality images also deliver visual proof for damage claims or bulky loads on train cars.

A full-scale service, from start to finish

- Both hard- and software are developed at the Camco Technologies headquarters in Belgium.

- We have a wide range of talents. This makes us agile and unique.

- 25 years experience, 300+ terminals. Tell us about your challenges.

We are looking forward to get inspired, and in a true partnership bring your automation project into a success.