Radar was once reserved for high-end automotive and military applications. Today, it’s at the core of several new Camco solutions. By pairing radar with AI, we’re pushing the boundaries of smart sensing — in terminals, at gates, and along the tracks.

From traffic barriers to train buffers, radar offers a powerful combination of robustness, reliability, and precision. Unlike technologies such as LiDAR, which struggle in fog, rain or dust, radar operates with ease in even the harshest environments. Add AI to the mix, and you get real-time object classification, motion detection, and noise filtering — all without the need for human intervention.

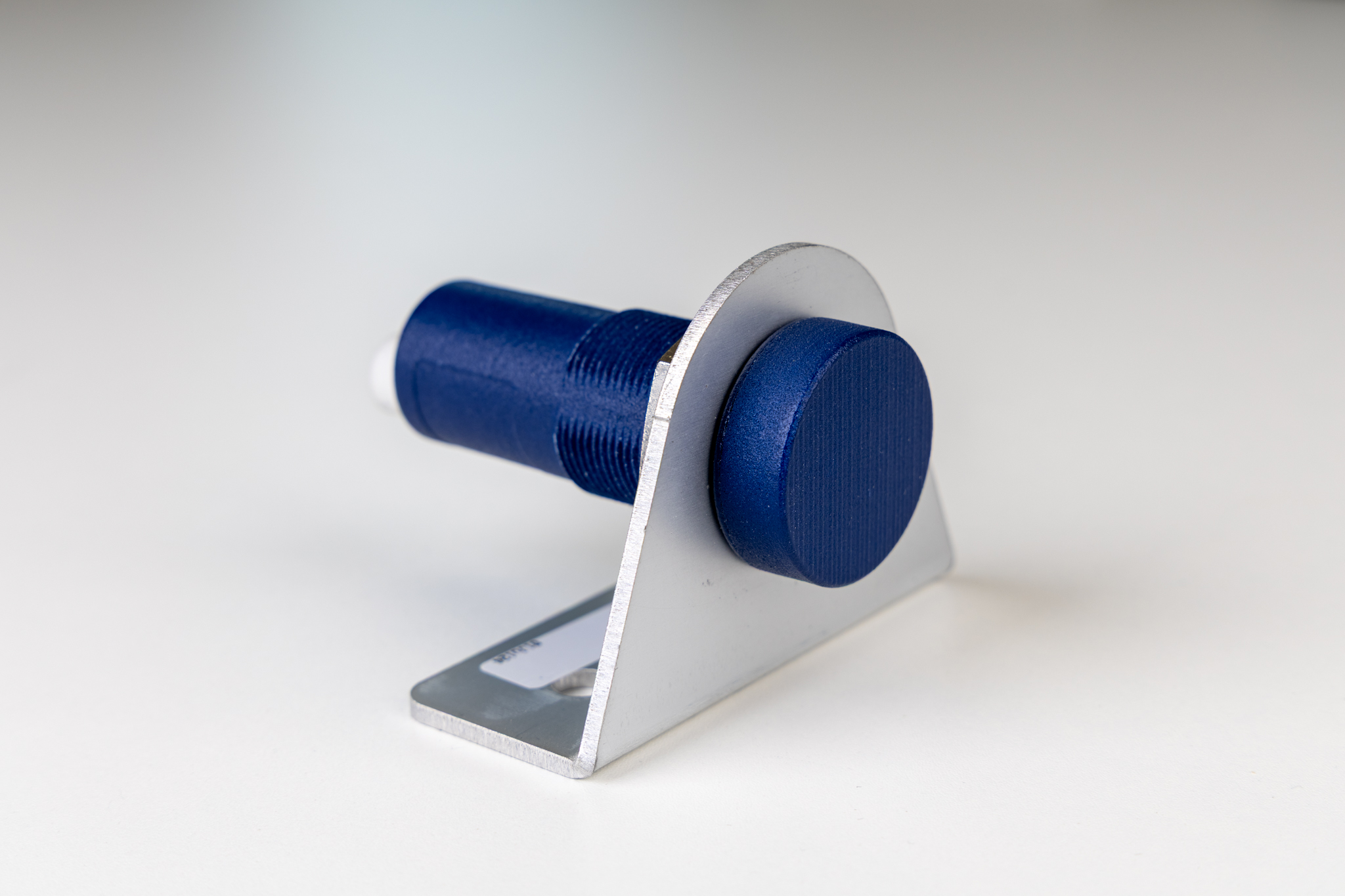

1. TriTech RFID Reader with radar

In 2024, Camco launched its own longrange RFID reader, built on the latest technology and fully compatible with EPC GEN2 and RAIN standards. This year, we enhanced the reader with a radar sensor and a camera.

Depending on the antenna type, the reader can scan tags in a lobe up to 12 meters long and 5 meters wide. In gate lane applications, we want to ensure we’re only reading tags from trucks that are actually stationary in the lane. The integrated radar confirms the presence of a vehicle and reduces false readings.

Another use case involves RTG or RMG operations, where the radar helps determine whether a tag belongs to a waiting truck — or one simply passing by in a different lane.

Radar is a game changer — not because it’s new, but because we now know how to use it smartly. By combining it with AI, we can deliver reliable, low maintenance sensing systems that perform in all conditions.

— Jan Bossens, CEO Camco Technologies

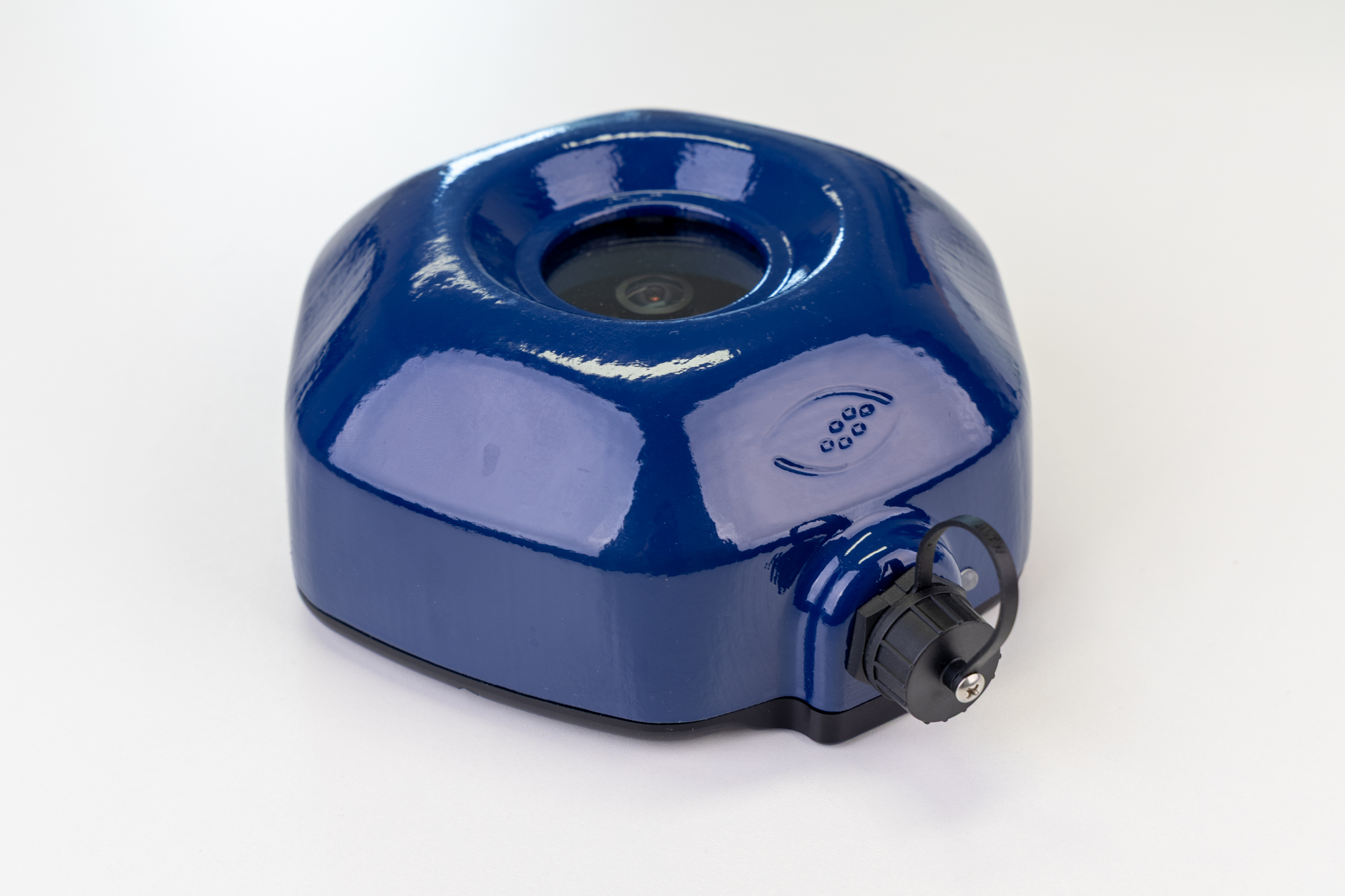

2. Traffic Barrier Sensor

One of Camco’s latest innovations is the radar-based sensor for traffic barriers. This new sensor replaces older ultrasonic models, which were more prone to failure in high winds and heavy rain. The radar sensor detects trucks or pedestrians under the barrier arm before it closes.

Some companies still use ground loops for this purpose, but ground loops cannot detect people. Our radar solution offers greater reliability and robustness, and is also more cost-effective — delivering better value for money. For ease of integration, we designed the new presence sensor in the same shape as the ultrasonic version, ensuring both mechanical and electronic compatibility.

3. Train Buffer Sensor (TBS)

The Train Speed Buffer Sensor (TBS) is a groundbreaking product from Camco, developed to replace the older LMS system. The LMS used a Sick laser scanner to measure train speed by scanning the wheels just above the rail. While it offered basic functionality — such as detecting wheel clusters (bumpers) and calculating speed — it was sensitive to installation errors and environmental factors like weeds, debris, fog, and dust.

The new TBS system is a much more reliable and robust alternative. It uses three radar sensors to accurately measure train speed, a camera system that detects wagon bumpers in real time, and an integrated AI processor. Unlike laser-based systems, radar is unaffected by fog, dust, or vegetation — making it far more dependable in terminal environments.

Currently being field-tested at CTB and Poko, the TBS is already showing marked improvements in the speed and efficiency of train inspections.

4. Empty Lane Sensor

Monitoring an empty lane on the landside of a stacking crane (ASC) using radar is significantly more reliable than camera-based systems. Radar doesn’t require any maintenance and performs consistently, regardless of weather or lighting conditions.

Camco continues to invest in radar-powered innovations

Not for the sake of novelty, but to bring practical, scalable, and resilient sensing solutions to the front lines of terminal automation. Radar and AI are no longer just supporting technologies — they’re becoming central to how we think about TRAFFIC BARRIER automation itself.